产品别名 |

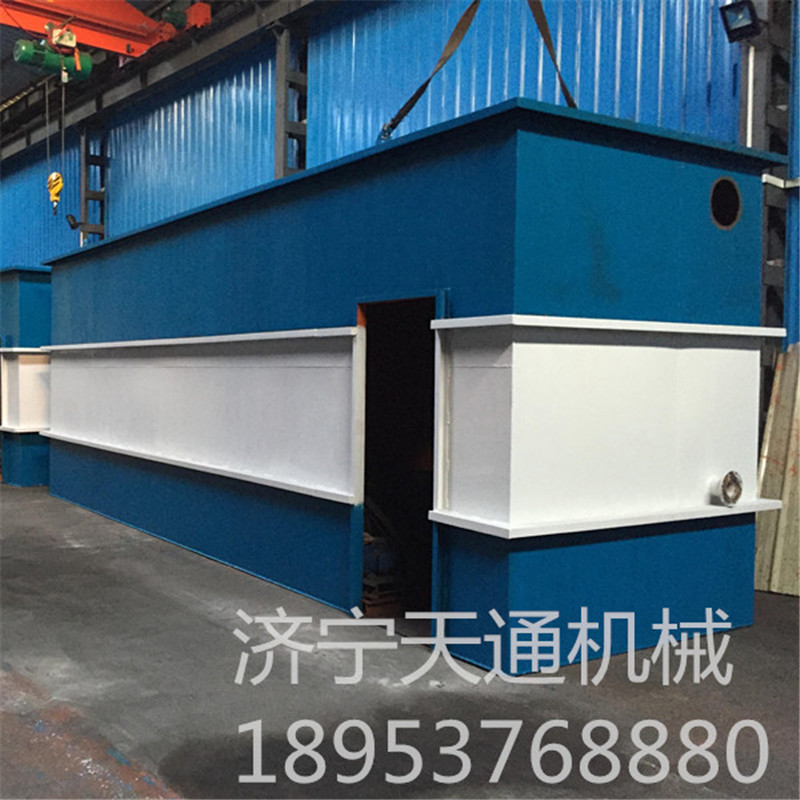

污水处理设备,养殖场污水处理设备,乳制厂污水处理设备,冶炼厂废水处理设备 |

面向地区 |

品牌 |

天通 |

|

规格 |

其它 |

加工定制 |

是 |

广东梅州天通养殖场污水处理设备定制

工艺简介:

经上述二级厌氧-气浮处理的消化液进入集水配水池,同时加入废冷却水(或达标水),控制废水COD在1000~1500mg/L之间,并底部予以曝气混合。然后泵入SBR好氧装置继续处理。废水在SBR池中,按顺序进行进水、曝气、沉淀、滗水排放,出水达到排放标准。

主要设计参数

Ⅰ级CSTR厌氧发酵罐:钢制,6座,单罐有效容积2000m³,发酵时间7.5d,容积负荷8~10kgCOD/(m³·d)。

Ⅱ级UASB反应器:钢筋混凝土结构,2座,单池有效容积1100m³,水力停留时间1.3d,容积负荷3.3 kgCOD/(m³·d)。

工程效益

该工程节能效果明显,每年可节煤1.65万吨,减排38.7万吨CO2,同时废水达标,环境污染得到治理。

工程总投资2500万元,年运行成本400万元。年获效益:(1)若按原煤热值500元/t计算,年回收425万元;(2)若按天然气热值计算,1m³沼气可获益1元,年回收1250万元。尚未计算肥料收益和免交的排污费收益。

工艺特点:

Ⅰ级CSTR厌氧发酵罐采用大型喷射泵搅拌和污泥回流装置,适用高浓度、高悬浮物酒精废液,该装置和工艺曾于1988年获我国国家科技进步奖。Ⅱ级UASB装置引进消化了2000年德国的“组合式双层三相分离器”设计。SBR装置采用了德国进口的硅橡胶膜微孔曝气管。

总结:

本公司坚持先分析客户的原水水质及环境条件,然后再进行有针对性的工艺设计,设立客户档案,同时为用户提供各种水处理工艺的可行性论证,技术咨询、生产制造、工程安装、调试培训等一系列技术服务,并向用户提供设备终身维护服务。公司以的技术、的设计、完善的售后服务欢迎新老客户前来咨询、参观和选购。

Process characteristics:

The first class CSTR anaerobic fermentation tank adopts large injection pump agitation and sludge reflux device, which is suitable for high concentration and high suspended solids alcohol wastewater. The device and technology were awarded the national science and Technology Progress Award in 1988. The second class UASB device introduced the advanced design of the "combined double layer three-phase separator" in Germany in 2000. The SBR device uses a silicone rubber membrane microporous aeration tube imported from Germany.

Summary:

The company adhere to the first analysis of raw water quality and environmental conditions of customers, and then the process of design, the establishment of customer files, and the feasibility of various water treatment process for the user, a series of technical consulting and technical services, manufacturing, installation, commissioning and training equipment, and provide life-long maintenance services to users. With advanced technology, first-class design, perfect after-sales service, the company welcomes the new and old customers to come to consult, visit and choose.