产品别名 |

污水处理,食品厂废水 |

面向地区 |

品牌 |

天通 |

|

规格 |

其它 |

加工定制 |

是 |

淀粉废水处理工程实例

Starch wastewater treatment engineering example

一 工程概况

Project overview

某公司主要生产玉米淀粉等产品,年产玉米淀粉20万吨,排放废水1000~1500m³/d。为了保护环境,防止废水对周围水体造成污染,该公司充分利用淀粉厂原有部分储罐,建设了一套处理能力为1500m³/d的废水处理设施。

A company mainly produces corn starch and other products, producing 200,000 tons of corn starch and discharging waste water of 1000~1500m cubed/d. In order to protect the environment and prevent the waste water from polluting the surrounding water, the company made full use of the original storage tank of the powder factory and built a waste water treatment facility with capacity of 1500m cubed/d.

二 处理工艺

1 生产工艺及水质

Two-process process

1 production process and water quality

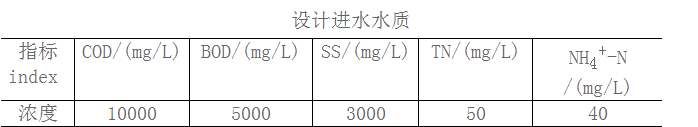

淀粉废水主要来源于玉米淀粉加工过程中的洗涤、压滤、浓缩等工艺段,用水量由于生产设备和生产工艺的不同,约为2~8m³水/t淀粉。根据该淀粉厂水质监测结果,同时参照国内部分相类似淀粉厂的排水水质实际情况,综合考虑各种因素,确定废水处理站的设计进水水质见下表:

Starch wastewater mainly comes from the process of washing, pressure filtration and concentration of corn starch. The water consumption is about 2~8m cubic water/t starch due to different production equipment and production process. According to the monitoring results of water quality starch factory at the same time with reference to domestic similar part of starch factory drainage water quality situation, comprehensive consideration of various factors, can design the water quality of wastewater treatment station to see the table below

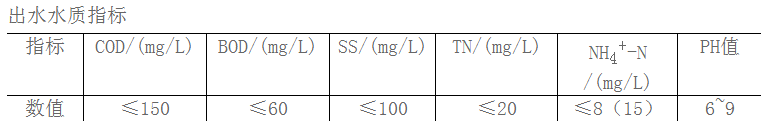

根据该市城市排水总体规划要求,淀粉厂处理出水排入城镇排水系统,由城市污水处理厂集中处理达标排放,故本工程排放执行《污水综合排放标准》(GB8978-1996)三级标准。但综合考虑城市发展规划及远期排放标准提高的可能,处理后的水质要求见下表:

In accordance with the requirements of the city's urban drainage planning, starch factory processing out of the water into the urban drainage system, the standard for central treatment of urban sewage treatment plant emissions, emissions of this project execution "integrated wastewater discharge standard" (GB8978-1996) level 3 standards. However, considering the possible improvement of urban development planning and long-term emission standards, the water quality requirements of the treatment should be shown in the following table:

2 处理工艺

本工程采用厌氧EGSB+好氧A/O处理工艺。厂区废水经过格栅初步分离去除粗大杂物后进入集水井, 经泵提升后进入初沉池进一步去除较小的SS颗粒物及大部分淀粉;初沉池出水自流进入调节池进行水量水质均衡调节;调节池出水自流进入到EGSB进水池,在进水池内进行温度调节、酸碱度调节后由提升泵打入厌氧EGSB反应池,在厌氧池内大部分有机物得以降解去除;厌氧池出水自流入后续A/O反应池进行好氧处理,好氧出水沉淀后达标排放。

厌氧池产生的剩余污泥可以单储存或者和好氧池的剩余污泥一起排入集泥池,经浓缩脱水机浓缩脱水后,泥饼外运填埋。

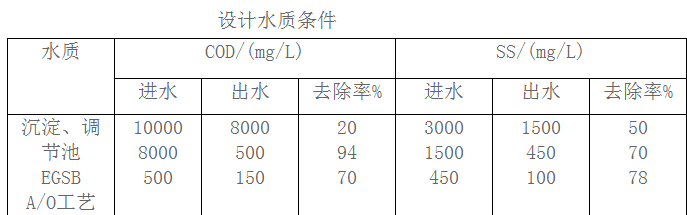

设计水质条件如下表

2 treatment process

This project adopts anaerobic EGSB+ aerobic A/O treatment process. After the initial separation and removal of coarse and large debris from the factory, the waste water was removed into the collecting well. After the pump hoisting, the small and small SS particles and most of the starch were further removed. The water quality is regulated by water flow into the regulating pool. Basin artesian water into the EGSB into the pool, conducted in into the pool temperature adjustment, ph adjustment after the lift pump into the anaerobic EGSB reaction pool, in most of the organic matter degradation to remove inside YanYangChi; The water from the anaerobic pool is discharged from the following A/O reaction pool for aerobic treatment, and good oxygen discharge is discharged after the precipitation.

The residual sludge produced by the anaerobic pool can be stored separately or together with the remaining sludge of the oxygen pool. After the concentrated dehydrator is concentrated and dehydrated, the mud cake is filled and buried.

The water quality condition is shown below

三 技术经济指标

该淀粉厂废水处理工程投资715万元,劳动定员9元,运行功率为140Kw。药费0.45元/m³,年运行费32万元,吨水处理费1.818元。

五 工程评析

本工程淀粉废水的BOD/COD值大于0.4,可生化性很好,因此采用生物处理工艺是合适的,以在尽量低的费用下,可靠地将有机污染物降到所要求的水平。厌氧工艺采用了高负荷的EGSB工艺,占地面积小,投资省。从运行结果来看,该工艺运行可靠,出水稳定达标。

Technical and economic indicators

The waste water treatment project of the factory is RMB 7.15 million, the labor is 9 yuan, and the operating power is 140Kw. The drug charge is 0.45 yuan/m to the third, the annual transportation fee is 320,000 yuan, and the water treatment fee is 1.818 yuan.

Five project analysis

Starch wastewater BOD/COD value of this project is greater than 0.4, the biological sex is very good, so the biological treatment process is appropriate, to ensure that as far as possible in the low cost, reliable to the required level of organic pollutants. Anaerobic process USES high - load EGSB process, small area, investment province. From the results of operation, the process is reliable and the water discharge is stable.

济宁天通是一家水处理设备生产和销售集一体的公司,公司拥有高的技术人才,拥有高素质的工作团队,可以及时地为客户提供完善的售后服务。我公司主要产品:水处理设备,污水处理设备、废水处理设备、工业污水设备、农业废水设备、雨水净水设备、医院污水设备、钢厂废水设备、屠宰场废水设备、食品厂废水处理设备等多种设备,可根据要求定制水处理设备。

Jining day pass is a set of water treatment equipment production and sales of the company, the company has sophisticated technology talented person, has a high quality work team, can provide customers with perfect after-sales service in a timely manner. My company main products: water treatment equipment, sewage treatment equipment, wastewater treatment, industrial wastewater, agricultural wastewater, rain water purification equipment, hospital sewage equipment, steel plant waste water equipment, slaughterhouse wastewater treatment equipment, food factory equipment and other equipment, can professional custom according to the water treatment equipment.